performed by

805 Marine Diesel Mechanic, providing expert mobile dockside service in

Ventura, Oxnard, Channel Islands Harbor & Santa Barbara.

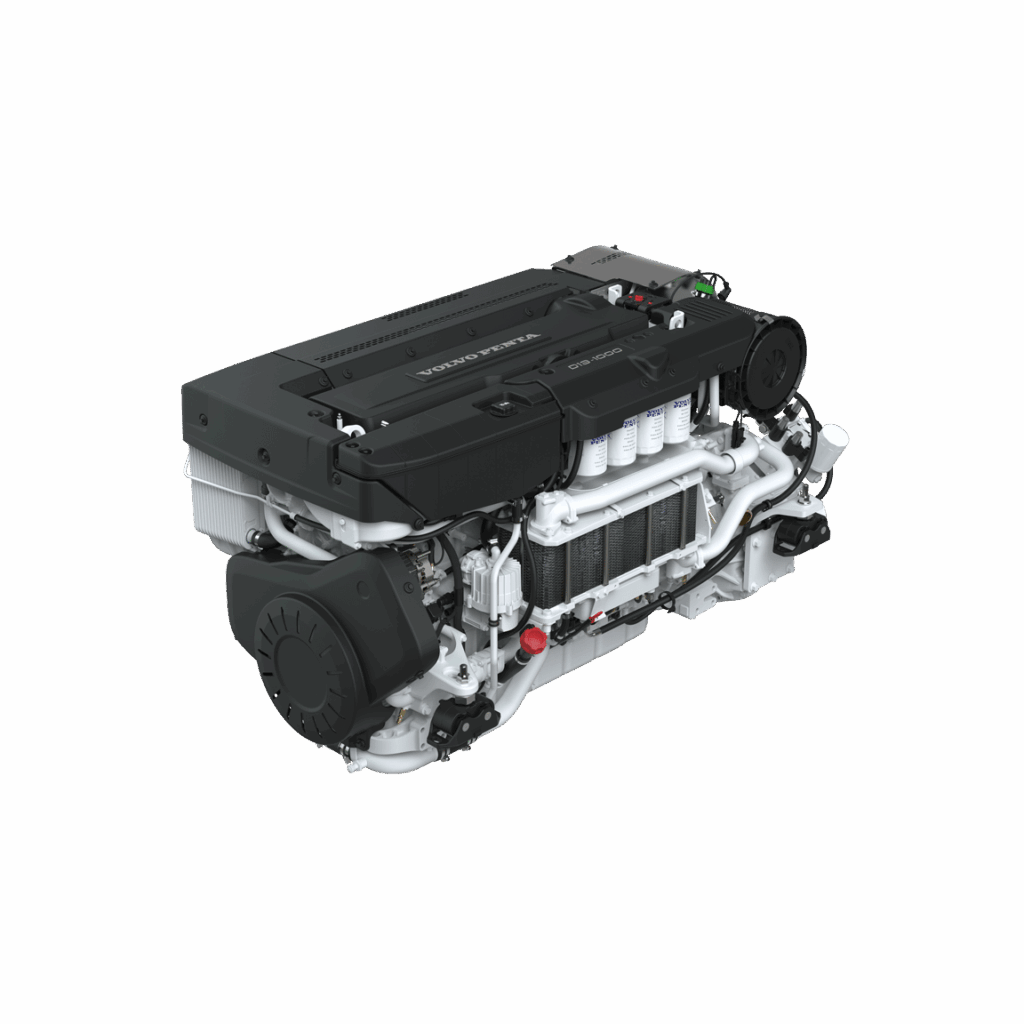

Keep Sailing Smoothly: Professional Volvo Penta Marine Diesel Services in Channel Islands

Reliable performance offshore starts with the right care for your

Volvo Penta marine diesel engine. 805 Marine Diesel Mechanic specializes in

maintenance, repair, and optimization of Volvo Penta D-series engines, ensuring smooth power

delivery, low fuel consumption, and dependable operation for boaters running out of Ventura,

Channel Islands, and Santa Barbara. From precision diagnostics to full overhauls, our certified

technicians keep your Volvo Penta D13 running at its best—so you can focus on the journey, not

the engine room.

Expert Volvo Penta Services

Comprehensive Engine Maintenance

Our Volvo Penta D13 maintenance programs are built around OEM schedules and

real-world operating conditions along the California coast. Services include:

- Routine oil & filter changes using OEM-quality components

- Cooling system inspections: seawater pumps, heat exchangers, and charge air coolers

- Fuel system care: water separators, spin-on fuel filters, injector checks

- Electrical & battery checks for reliable 24V starting & charging

- Full visual inspections for leaks, corrosion, worn belts, and hose issues

Proactive maintenance improves fuel economy, protects major components, and dramatically reduces

unplanned downtime.

Reliable Marine Diesel Repairs

When something isn’t right, 805 Marine Diesel Mechanic provides accurate,

standards-based Volvo Penta repair, including:

- Cylinder head, valve train, and piston servicing for proper compression

- Turbocharger diagnosis, cleaning, and replacement to restore boost and efficiency

- Injector and high-pressure fuel system repairs for clean, consistent combustion

- Cooling system rebuilds to eliminate overheating risks

- Electronic & EMS-related troubleshooting using advanced diagnostic tools

All work follows Volvo Penta specifications and uses OEM-grade parts to restore factory-level

performance.

Advanced Engine Optimization

For operators who want maximum performance and economy, we offer

Volvo Penta D13 engine optimization:

- Fine-tuning fuel injection timing and calibration

- Adjusting turbocharger & boost behavior for responsive yet efficient power

- Monitoring exhaust and emissions components to maintain Tier-compliant operation

- Customizing ECU parameters to match hull type, load profile, and duty cycle

The result: smoother acceleration, quieter running, lower fuel burn, and longer engine life.

Volvo Penta D13-700 – Key Specifications

The Volvo Penta D13-700 is an in-line 6-cylinder, 12.8-liter marine diesel

engine designed for robust performance and exceptional fuel efficiency.

Core Highlights

- Power Output: 700 hp (515 kW)

- Displacement: 12.8 liters

- Configuration: In-line 6-cylinder, 4-stroke diesel

- Injection System: High-pressure electronic unit injectors

- Camshaft: Overhead, four valves per cylinder

- Turbocharger: Twin-entry turbo with water-cooled exhaust manifold

- Cooling System: Seawater-cooled plate heat exchanger + freshwater circuit

- Lubrication: Integrated oil cooler, twin full-flow spin-on filters, by-pass filter, gallery oil-cooled pistons

- Electrical System: 24V/110A alternator (optional second 24V/110A)

- Emissions: IMO Tier II & EPA Tier 3 compliant

Engine & Block Design

- Cylinder block & one-piece cylinder head in cast iron with ladder frame

- Replaceable wet cylinder liners, valve seats, and guides

- Drop-forged crankshaft with induction-hardened bearing surfaces and seven main bearings

- Four-valve-per-cylinder layout with centered unit injectors and crossflow ports

- Gallery oil-cooled cast aluminum pistons with three piston rings

- Flexible engine mounts reduce vibration and noise

Fuel, Air & Cooling Systems

- Electronic high-pressure unit injectors with gear-driven fuel pump

- Volvo Penta EMS (Engine Management System) for precise control

- Twin-entry turbo with freshwater-cooled charge air cooler

- Air filter with replaceable inserts

- Seawater-cooled plate heat exchanger and coolant system prepared for hot water outlet

- Easily accessible seawater pump at flywheel housing

Electrical, Controls & Gears (Options)

- Complete instrumentation with alarms & EVC (Electronic Vessel Control) monitoring

- Electronic shift & throttle, plug-in connectors, and color displays

- Reverse gear options: ZF325-1AE or MGX-5096A with QuickShift® low-speed features

Together, these features deliver low noise, low fuel consumption, and long-term durability—ideal

for both commercial and high-end recreational vessels.

Why Choose Professional Volvo Penta Marine Diesel Services?

Saltwater, high loads, and long operating hours push even the best engines hard. Professional

servicing by 805 Marine Diesel Mechanic provides:

- Expert diagnostics with Volvo Penta-compatible EMS and EVC tools

- OEM-quality parts to maintain reliability and warranty alignment

- Preventive maintenance schedules that reduce costly failures

- Engine optimization for fuel savings and clean emissions

- Local dockside service in Ventura, Oxnard, Channel Islands & Santa Barbara

Investing in expert care extends engine life, boosts safety, and keeps your Volvo Penta D13 ready

for every run offshore.

Serving Ventura, Channel Islands & Santa Barbara

805 Marine Diesel Mechanic supports:

- Ventura Harbor – Fishing fleets, charter operators, and private yachts

- Oxnard & Channel Islands Harbor – Commercial vessels and recreational craft

- Santa Barbara Harbor – Workboats, ferries, and pleasure boats

Our mobile dockside units bring certified Volvo Penta expertise straight to your slip, minimizing

downtime and haul-out costs.

Why Boat Owners Trust 805 Marine Mechanic

- 30+ years of marine diesel experience

- Specialized Volvo Penta knowledge

- Family-owned with a customer-first approach

- Certified technicians & OEM parts

- Full-service support from routine maintenance to major rebuilds

View Volvo Penta Maintenance Schedule

One Response